If you’re a product manufacturer, you might be thinking of producing your own injection-molded plastic parts. If so, this blog will share with you some useful tips on how to do it safely.

What is Plastic Injection Molding?

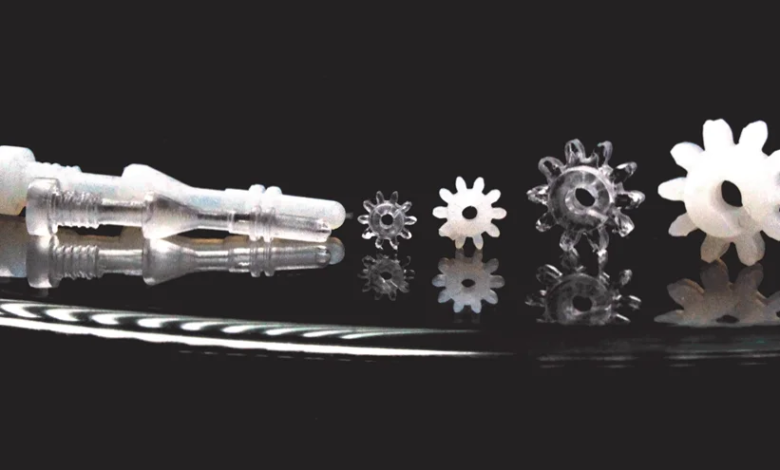

Plastic injection molding is a manufacturing process that creates plastic products by injecting molten plastic into molds. The molten plastic is then forced under high pressure through the mold, creating the desired product. This process is often used to create products such as toys, household appliances, and medical equipment.

Why Use Plastic Injection Molding?

There are many reasons why you may want to use plastic injection molding. For one, it’s a fast and efficient way to produce products. With Plastic Injection Molding, you can quickly turn a design into a physical product. Additionally, Plastic Injection Molding offers many benefits over other manufacturing methods. For example, it’s environmentally friendly because it doesn’t require any paint or other coatings. Additionally, Plastic Injection Molding is tough and durable, making it perfect for products that will be subjected to heavy use or abuse.

How Does Plastic Injection Molding Work?

What makes PIM different is how it’s used. With traditional manufacturing methods, products are made one at a time. This means that each product has to be made separately and requires a lot of labor and time. With PIM, however, products can be made in large quantities quickly and with little labor. This is because PIM machines use robots to do the injection process.

Conclusion

If you’re looking to manufacture your own products, then Huapin plastic injection molding services might be the answer for you. Plastic injection molding is a process that uses melted plastic to create objects out of it — think things like toys, jewelry, and even kitchen appliances. It’s a very versatile process and can be used to produce a wide variety of products.